Alinol®

Protective-decorative mixture

SPC Corrosion Protection offers the highest quality mixture «GALVANOL®», which is used as cold galvanizing. This mixture ensures 100 per cent anticorrosive protection of the metal, which is typical for other ways of metal galvanizing. We offer protective decorative metal polymeric aluminium-rich mixture «ALINOL®» as well. Bothe mixtures are ready-to-use and are easily applied on the metal surfaces by any convenient way of application at temperature from -30оС up to +50оС at any humidity.

TECHNICAL SPECIFICATIONS OF PROTECTIVE-DECORATIVE MIXTURE «ALINOL®»

| Film outlook | After drying the film should even, homogenous, without foreign matters and stains, glossy |

| Film color | Metallic |

| Viscosity | 40 с |

| >Mass fraction of solids | 26% |

| Drying time to level 3 at 20°С | 20-30 min |

| Complete drying time | 24 hours |

| Operational conditions | from -30°С to +50°С |

| Transverse film elasticity, mm | 2 |

| Adhesion, point | 1 |

| Density at 20°С | 950 kg/m3 |

| Lifetime | Not limited |

| Packing | Can, 18 kg |

| Solvent | Petroleum solvent |

| Coverage rate | 130-150 g/m2 |

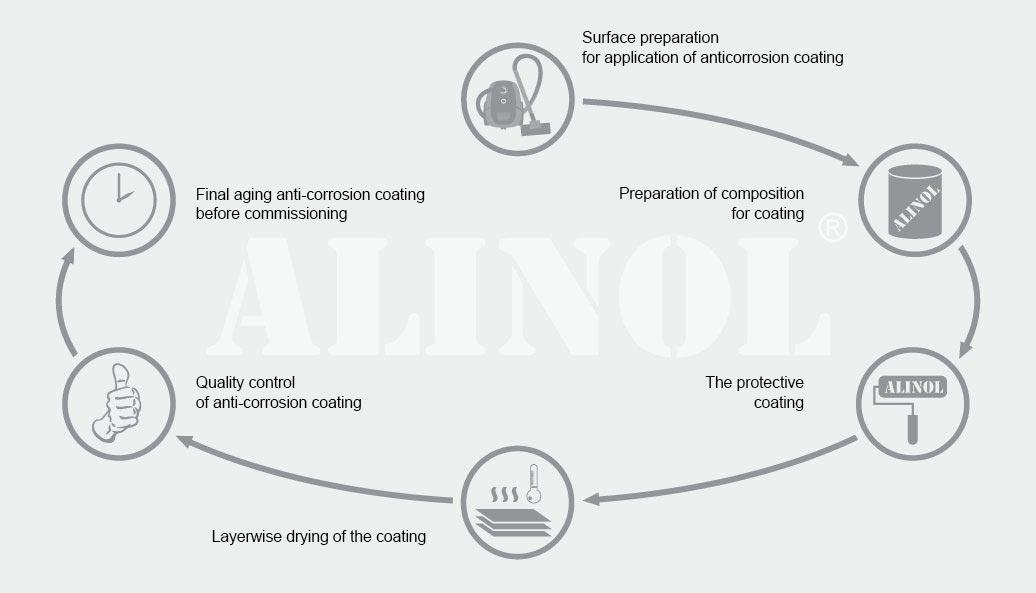

TECHNOLOGY OF APPLICATION OF «ALINOL®» MIXTURE

- Surface preparation for application of protective coating;

- Preparation of mixture for application;

- Application of protective coating;

- Layer drying of coating;

- Quality control of protective coating;

- Final holding of protective coating before commissioning.

It is recommended to apply finishing protective-decorative coating at the temperature not lower than 30°С.

During carrying out of outdoor anticorrosive protection in wintertime it is necessary to:

- Build shelter to protect from precipitation;

- Metal surface temperature should be on + 3°С higher than dew point.

PREPARATION OF THE METAL SURFACE BEFORE THE APPLICATION OF «ALINOL®» COATING

Before the application of the finishing protective-decorative coating «ALINOL®» the metal surface should be coated with the anticorrosive coating «GALVANOL®».

The application of the mixture on the surfaces not coated with anticorrosive mixture «GALVANOL®» is not allowed.

All parts of articles that are subject to protection should be accessible for inspection, surface preparation, and application of protective coating and its quality control.

Surface and/or elements that are subject to preparation before application of protective-decorative coating «ALINOL®» should be free of dust.

The mixture is applied on clean and degreased surface not later than after 12 hours, if metal constructions are outdoors and 48 hours, if indoors.

PREPARATION OF «ALINOL®» MIXTURE

Finishing protective-decorative mixture «ALINOL®» is ready for use and application by spray tank gunwith nozzle diameter 2.0 mm. The material can be diluted with solvents (petroleum, coal-tap), xylene, if necessary.

Dilution of finishing protective-decorative mixture «ALINOL®» with other solvents is not allowed.

«ALINOL®» mixture should be should be thoroughly stirred with mixer till total homogeneity and stirred before each loading of the tank gun.

APPLICATION OF «ALINOL®» MIXTURE

The mixture is applied on clean and degreased surface not later than after 12 hours, if metal constructions are outdoors and 48 hours, if indoors. Despite of chosen method of application of mixture on prepared surface, welds and hard-to-reach places should be firstly painted by brush.

In case of cracks and hidden openings after welding eliminate possibility of ingress of moisture into them (by any nonpolluting means of waterproofing).

Finishing protective-decorative coating «ALINOL®» should be applied on the surface exclusively with paint sprayer.

«ALINOL®» mixture is applied on the surface by hydraulic spraying method. Equipment should be free of containment and previously used painting materials. Dilute, if necessary, with solvent or xylene in the ratio till 5% by weight. Air pressure – 0.2 – 0.3 mPа (2 – 3 bar). Nozzle diameter – 2.0 mm. Working mixture of protective-decorative coating «ALINOL®» should be stirred regularly (each 20-30 minutes). Mixture should be applied layer-by-layer, covering edge of the previous line. The total thickness of the coating should be min 40 µm — max 160 µm. Applied on constructions with minor mechanical strains, maximum thickness of application can be increased to 200 mkm.

All application works are carried out at –30° - +50°С and relative humidity up to 90%.

The mixture can be applied on wet surface. But the surface should be free of moisture as drops and at negative temperatures avoid crust of ice. It is recommended to use shelters in application of coating under rain or snow conditions.

Finishing protective-decorative coating «ALINOL®» should be applied on the surface exclusively with paint sprayer.

COVERAGE RATE OF THE FINISHING PROTECTIVE-DECORATIVE COATING «ALINOL®»

When applying finishing protective-decorative coating «ALINOL®» on the metal surfaces its converge rate is 150 g/m2 subject to correct application technology.

ANTICORROSIVE WORKS QUALITY CONTROL

| Quality of anticorrosive works is controlled both during implementation of separate operations and after completion of whole set of works. Quality of coating is controlled by means of external examination. After polymerization the coating should be free of through pores, blisters and visual damages. Thickness of coating is controlled after drying with thickness gauge. |

DEFECT ELIMINATION AND REPAIR

| Defect spots (peeling, blistering) occurred during coating application and operation is subject to immediate elimination. Rub down the defect spot with sandpaper, degrease and dry. Apply anticorrosive coating on prepared surface according to application procedure. Thickness of coating on metal surface is measured with thickness gauge. |

TRANSPORTATION AND STORAGE

| «ALINOL®» mixture is shipped by any means of transportation in covered transportation means according to shipping rules applicable on each type of transport. The material to be stored in close ventilated warehouses or under shelter at maximum temperature 35°С. If stored under higher temperature manufacturer does not guarantee meeting of specification requirements. «ALINOL®» material should be stored in tightly closed containers, excluding ingress of moisture, dust and other containment. |

MANUFACTURER’S GUARANTEE

| Manufacturer guarantees meeting the requirements of specification under meeting the transportation and storage requirements and application guide. Guaranteed storage life of material is unlimited. |